H2FUTURE project: use of renewable energy resources to produce hydrogen

11-05-2017

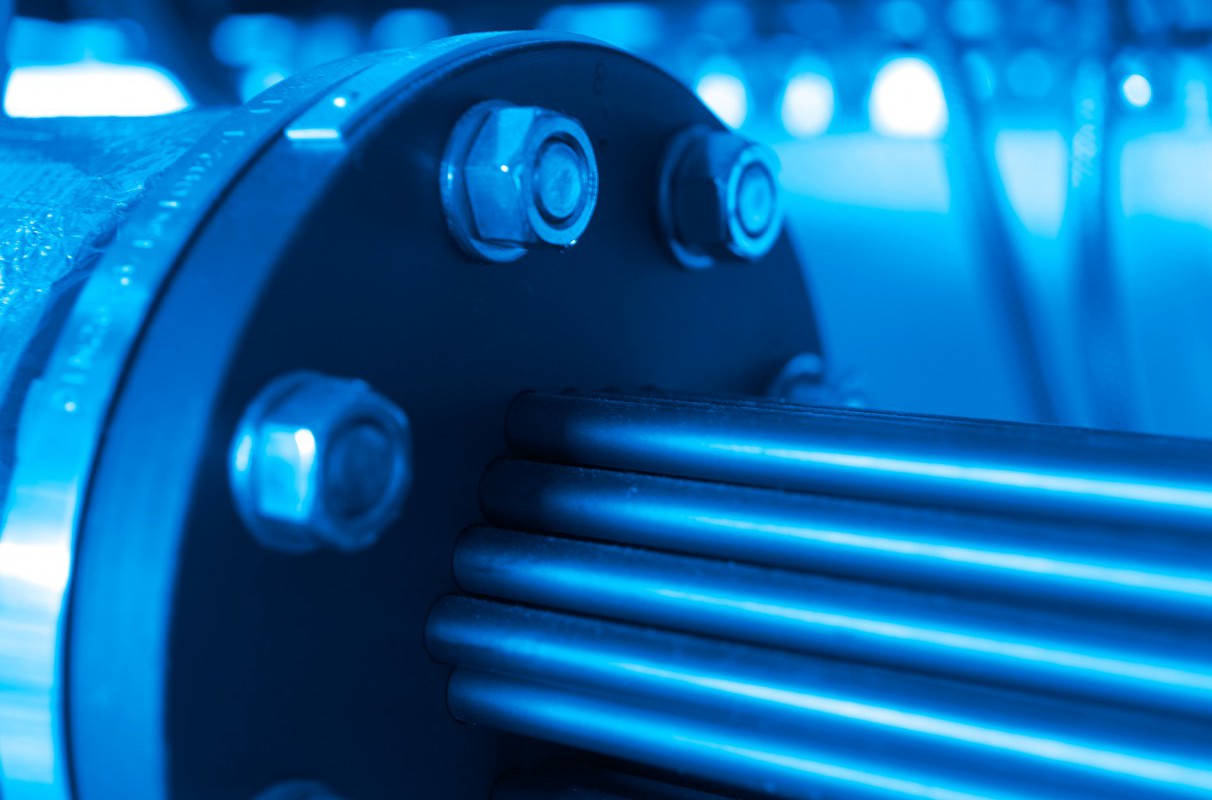

VoltaChem co-initiator ECN is partner in the H2FUTURE project. This project will provide valuable insights in the field of using renewable energy resources to produce hydrogen. At the steel factory of Voestalpine in the Austrian city of Linz, one of the world’s largest and most cutting-edge electrolysis installation will arise. Siemens' Proton Exchange Membrane (PEM) electrolysis device, with a power consumption of 6 MW, will use renewable energy sources to produce hydrogen.

VoltaChem co-initiator ECN is partner in the H2FUTURE project. This project will provide valuable insights in the field of using renewable energy resources to produce hydrogen. At the steel factory of Voestalpine in the Austrian city of Linz, one of the world’s largest and most cutting-edge electrolysis installation will arise. Siemens' Proton Exchange Membrane (PEM) electrolysis device, with a power consumption of 6 MW, will use renewable energy sources to produce hydrogen.

Besides VoltaChem co-initiator ECN and Siemens, the consortium of this H2FUTURE project consists of Voestalpine, Verbund and K1-Met. Project coordinator Verbund will supply the electricity, the Austrian Voestalpine will apply the hydrogen technology in the steel factory, K1-MET and ECN are responsible for the scientific evaluation of this demonstration project.

"Technically speaking the use of the PEM technology for an electrolysis process is the biggest challenge", says ECN's Marcel Weeda. "Up until now most large electrolysis projects use alkaline technology, that has already proved its effectiveness. "But PEM electrolysis is more favorable because of its higher energy efficiency, better dynamic performance, smaller dimensions and potentially lower production costs." Weeda points out that if the electrolysis process wants to play a significant role, scaling up to several dozens of megawatts is necessary. "What will be the best way to deliver the scale-up, experience in practice will show", Weeda says. "That's what projects like these are for. After this installation of 6 MW the next demonstration project will get a power capacity of 10 MW. Eventually we strive for units with capacities of 50 to 100 MW which can be combined into plants with a multitude of that capacity.

More sustainable steel industry

According to Weeda the hydrogen that will be produced, among other things, has to result in a more sustainable steel industry. "In Texas for example Voestalpine has a steel factory that splits natural gas into hydrogen and carbon monoxide in order to produce iron in a reduction process", he explains. " In this process you could easily gradually use hydrogen from the PEM installation to develop a carbon free steel production process."

Source: Technisch Weekblad

Link with VoltaChems Power-2-Hydrogen Program Line

This project perfectly matches VoltaChems Power-2-Hydrogen Program Line that looks at the production of hydrogen, and subsequent reactions such as ammonia synthesis. This program line also includes research for more efficient electrolytic PEM (proton exchange membrane) electrolyzers and promotes the large-scale application of electrolyzers, like the H2Future project.

Please watch the H2Future video below:

Share this page: