Hybrid industrial energy systems: Kick-starting industrial electrification

22-01-2018 | Program update | P2Heat

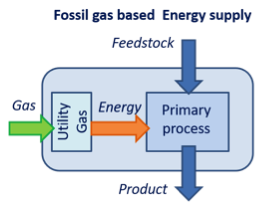

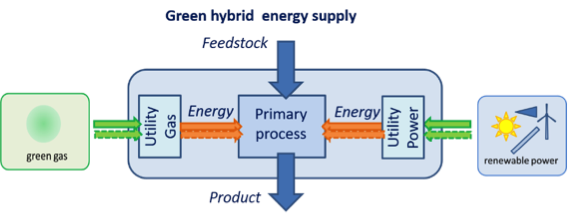

One of the most promising short-term industrial electrification technologies is power-to-heat, the switch from gas- to electricity-based heat. As many industrial processes are driven by medium and high-temperature heat, changing its energy source to renewable power will immediately impact the industrial carbon footprint. In the VoltaChem program a group of companies, together with TNO and ECN, has recently started a project that will drastically improve the business case of power-to-heat using a hybrid energy system. At times when a lot of renewable electricity is available from the sun and wind, gas fired heat generation switches off and process heat is generated from sustainably generated electricity.

One of the most promising short-term industrial electrification technologies is power-to-heat, the switch from gas- to electricity-based heat. As many industrial processes are driven by medium and high-temperature heat, changing its energy source to renewable power will immediately impact the industrial carbon footprint. In the VoltaChem program a group of companies, together with TNO and ECN, has recently started a project that will drastically improve the business case of power-to-heat using a hybrid energy system. At times when a lot of renewable electricity is available from the sun and wind, gas fired heat generation switches off and process heat is generated from sustainably generated electricity.

An industrial hybrid energy system requires technology that can switch smartly and seamlessly between gas and electricity so that production processes run smoothly. The consortium will work on this solution in the project ‘Industrial Hybrid Energy System’, which started Friday, January 19th, 2018, as part of the VoltaChem program. Heat generation of electricity, also known as Power-2-Heat - one of the four VoltaChem program lines - can be realized in the short term and is a first step in the transition to full electrification of the industry, making the use of fossil fuels unnecessary.

Electrification as a strategic choice

The Dutch industry alone uses around 530 Petajoules (PJ) per year in the heat for production processes, mainly generated by fossil fuels such as natural gas and oil. But new innovative technologies, fluctuations in the prices of electricity and the growth in the supply of affordable renewable electricity make electrification an attractive and strategic choice. The solution that the consortium will develop will be widely applicable in various industrial processes.

Power-2-Heat as technology for transition

Electrification of the industry will only be acceptable for society when the electricity comes from renewable sources thereby achieving a significant CO2 reduction. As business cases will gradually develop, this will require hybrid and flexible solutions on a short term. The solution that the consortium partners work on in this VoltaChem project consists of a hybrid system in which smart switching between the existing gas installation and sustainable sources is possible. The industry thus benefits from the growing supply of renewable electricity and also contributes to the stability of the electricity grid. The new hybrid system builds on the years of Demand Response experience, including the PowerMatcher technology, which makes it possible to incorporate more sustainable energy into the electricity grid.

Insight into the value of flexibility

Sympower, Scholt Energy Services, eRisk Group and TNO will work together on the flexible and seamless circuit between gas and electricity. The switching moments will depend on factors such as an increasing supply of solar and wind energy and falling energy prices. Alliander and TNO will look at the effect of (fictitious) variable transport and capacity tariffs (Kwmax). The project also makes a prediction of the value development of flexibility in different scenarios, such as the strong growth of wind at sea and the closure of coal-fired plants.

Experience in practice

The hybrid energy system will be tested and demonstrated at three companies: compound feed company E.J.Bos, oil and grease supplier Sime Darby Unimills and Emmtec Services, a utility provider that supplies steam to various customers on the business park of the same name. In this pilot Huikeshoven and ECN, we are working on the design and installation of an electric heating element of 1-3 megawatts (MW) in the existing degasser of Emmtec Services. The pilot tests will examine the effects of electrification on the primary production process. The project will last three years, has a size of 1.5 million euros and has been made possible by the top sector Energy.

There is a possibility in the project to study more Power-2-Heat user cases and short-term opportunities. So industrial companies, as well as hardware suppliers and energy companies, are invited to contact one or our VoltaChem team members: Yvonne van Delft or Lennart van der Burg. You can also subscribe to our VoltaChem community. We look forward to helping you implement your ideas!

Share this page: