Changing from Thermal to Electrochemical Conversion

22-09-2015

What are the benefits of changing from thermal conversion to electrochemical conversion for the chemicals industry? This is the question being investigated by VoltaChem's TNO. The first demonstration case concerns the conversion of HMF from biomass to FDCA, an important raw material for the chemicals industry.

What are the benefits of changing from thermal conversion to electrochemical conversion for the chemicals industry? This is the question being investigated by VoltaChem's TNO. The first demonstration case concerns the conversion of HMF from biomass to FDCA, an important raw material for the chemicals industry.

Soon however, we will be able to apply the knowledge thereby accrued to the development of electrochemical (oxidation) reactions.

The supply of fossil fuels is becoming exhausted. It is expected that the future use of electrical energy will become cheaper and more sustainable. Within the framework of the joint programme with ECN on the issue of electrification of the chemicals industry, TNO is investigating the opportunities for applying electrical energy by performing chemical conversion using electrochemical methods instead of thermal methods. As regards oxidation reactions, which small-scale chemistry is mostly about, electrochemical conversion also often leads to greater selectivity and to a better conversion than that offered by a traditional process.

A STEP TOWARDS PRACTICAL APPLICATION

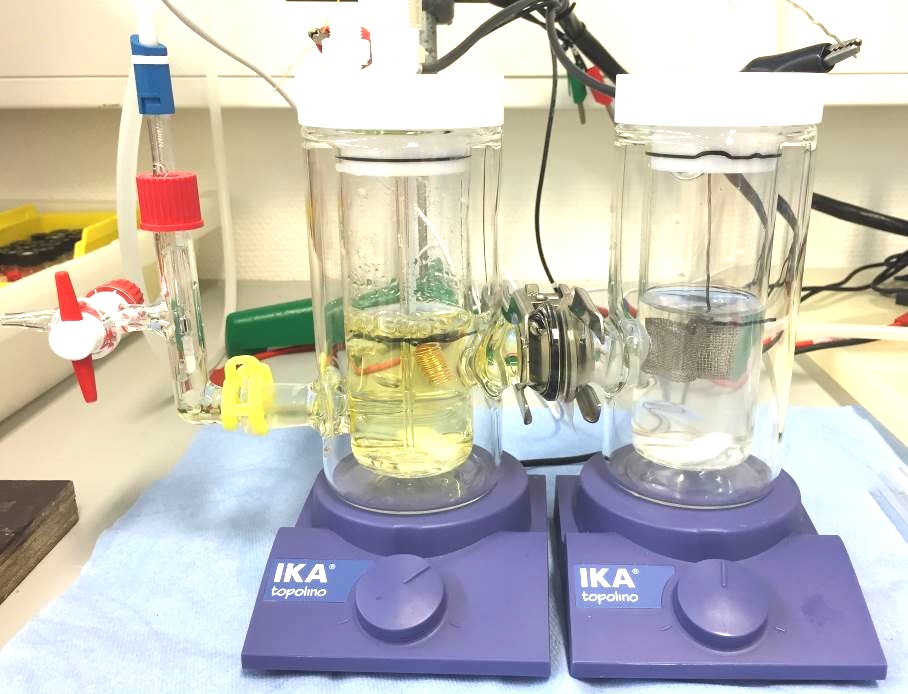

"What you often see is that electrochemical research is academically orientated", explains project manager Raymond Creusen of TNO. "A study of the mechanism involves the conversion of low concentrations on a very small scale. In this project we take a step towards its practical application. This means that we scale up to a process involving a content of several litres and the application of much higher applications. Whereas academic research usually only involves very low concentrations (one gram per litre), in this first demonstration case we convert 100 grams of raw material per litre inside the reactor. This makes considerable demands of the engineering of the process, both in terms of the conversion and the reprocessing processes. Finally, from a financial perspective, you want to be left with as high as possible product concentration and purity."

GENERIC PROCESS PARAMETERS

Furandicarboxylic acid (FDCA) can be used, for example, for the production of sustainable plastic bottles, an invention of the Dutch company Avantium. The conversion of hydroxymethylfurfural (HMF) into FDCA should be regarded primarily as an example that further emphasises the attractiveness of electrochemical oxidation. Creusen: "As well as identifying the specific aspects of the chosen reaction, we will be defining crucial generic process parameters for electrochemical oxidation. We will then be able to apply our acquired knowledge to relatively quickly assess the usefulness of other electrochemical oxidations. On top of that, we are investing in equipment to enable us to carry out electrochemical oxidations and other electrochemical conversions in a short time, on a laboratory scale, and in a small pilot scale, including the purification steps following on from this."

MORE INFORMATION?

The process has to be completed by the end of 2016. "The industry benefits when we can demonstrate how a total process has been designed in order to create a product. It is this which makes the work so exciting. You aren’t just creating a few steps on the journey, but developing a complete process, from beginning to end. You start with a raw material and use it to create a product with real value. I am really happy to discuss this further with companies eager to learn whether they too could benefit from electrochemical conversion."

Share this page: