Modeling aging and degradation of stacks for a gigawatt electrolyzer

26-02-2020 | New Project | P2Hydrogen

As part of the third phase of the Dutch national GigaWatt Electrolyzer project, VoltaChem founding partner TNO will develop a model for aging and degradation of PEM and alkaline electrolyzer stacks. This will provide the foundation for a stack replacement strategy in a future hydrogen factory of gigawatt scale.

As part of the third phase of the Dutch national GigaWatt Electrolyzer project, VoltaChem founding partner TNO will develop a model for aging and degradation of PEM and alkaline electrolyzer stacks. This will provide the foundation for a stack replacement strategy in a future hydrogen factory of gigawatt scale.

To secure the future availability of green, CO2-free hydrogen in the Netherlands, multiple gigawatt-sized electrolysis plants will be needed. In addition to producing sustainable hydrogen for industry, these can contribute to a future flexible energy infrastructure in which hydrogen acts as an energy carrier. However, realizing such plants requires a thousand-fold increase of the current state-of-the-art electrolyzer performance. VoltaChem founding partner TNO is core partner in the project 'Gigawatt Electrolysis Plant', that sets out to make this happen.

Kicked-off in 2018 and coordinated by the Institute for Sustainable Process Technology (ISPT), the GigaWatt project is aimed at developing a conceptual design and a transparent cost estimation methodology for a 1-GW electrolyzer plant. It will be fit for implementation in 5 industrial regions, ready for start-up in 2025 – 2030 and delivering hydrogen at an economically viable cost level. The project consists of three parts that are carried out in parallel and in an iterative character. Part 1 delivers a design of electrolyzer stacks and modules, a heat management model, a CAPEX learning curve, an electrolyzer operating model. Part 2 delivers the context of 5 industrial regions in terms of regional demands, infrastructure and plot size, including system integration options and feasibility assessment. Part 3 will deliver an integrated conceptual design, including the expected economics for plant erection in 2025-2030.

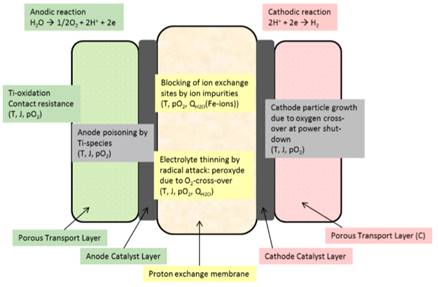

As part of the project, we are now starting research on the modeling of aging and degradation of electrolyzer stacks as a function of parameters such as temperature and pressure in the stack and changes in load. This is of great relevance to managing the operating conditions and the stack replacement strategy in a factory of gigawatt scale. Aspects of the study will be the modeling of the state of health of a stack under different operating strategies; modeling networks of multiple stacks as a result of variations in individual stack performance; and a first analysis of the impact of the stack and system design on maintenance.

Are you interested in the GigaWatt study? Please contact Lennart van der Burg, business development manager of Power-2-Hydrogen.

Share this page: