New stress testing protocol accelerates PEM electrolyzer lifetime assessment.

22-02-2018 | Project results | P2Hydrogen

PEM electrolysis is a key technology to make efficient use of the fluctuating supply of renewable electricity in the future. Therefore it should be able to handle fluctuating loads. However, it is not well known what the impact of dynamics on electrolyzer degradation is. ln the ELECTRE project ECN and Hydron Energy have started investigating degradation phenomena. A key result of the project, which has just been finalized, is the development of an accelerated stress testing (AST) protocol that will help companies to quickly assess component durability.

PEM electrolysis is a key technology to make efficient use of the fluctuating supply of renewable electricity in the future. Therefore it should be able to handle fluctuating loads. However, it is not well known what the impact of dynamics on electrolyzer degradation is. ln the ELECTRE project ECN and Hydron Energy have started investigating degradation phenomena. A key result of the project, which has just been finalized, is the development of an accelerated stress testing (AST) protocol that will help companies to quickly assess component durability.

Degradation is a complex process

Components in the electrolyzer, such as membranes, current collectors, and catalyst operate in an environment that promotes rapid degradation. By selecting mild operating conditions electrolyzer cells can achieve > 50000 hours of lifetime. However, to obtain higher efficiencies and lower investment cost, the electrolyzer needs to operate at more challenging conditions. At which conditions a large number of processes occur which lead to a decline in performance. Not only do the operating conditions impact the rate of degradation of the individual degradation process, there is also a complex interaction between the degradation mechanisms.

Improving electrolyzer components

Better components for electrolyzer are cheaper and show less degradation. The first step in the development of novel components is, therefore, to be able to assess the degradation rate of these components and compare them currently used components. Testing for 1000’s of hours under different operating conditions is not feasible. Therefore the project partners in VoltaChem’s ELECTRE project developed standard protocols for accelerated testing whereby the electrolyzer is submitted to harsher conditions. An extensive review of the knowledge on degradation mechanisms underlies these accelerated stress testing protocols.

Next steps: component development

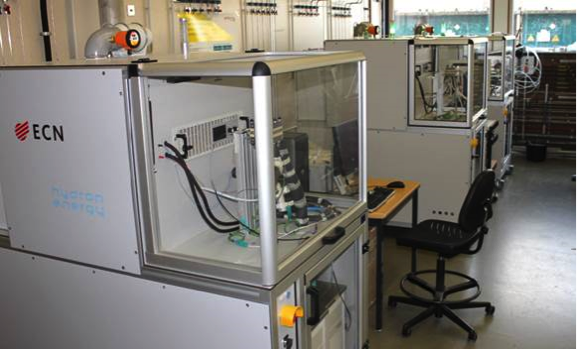

The developed test protocols are currently under evaluation in a working group led by the European Joint Research Centre (JRC) to come to international harmonization of electrolyzer testing. In addition to the test protocols, the project partners have developed a robust test station design. Three units have been built in the project and are now used for duration testing and accelerated testing. Hydron plans to develop the test station as a commercial product. At ECN the number of test stations will be increased and used to develop improved components together with Dutch SME’s.

New project: AMPERE

A follow-up project, AMPERE, focussing on improving the membrane has recently started with project partners PTG/e and FujiFilm. Within this project, we are building a broad industrial interest group of SME’s that has technology and knowledge in-house, which can be applied to improve the electrolyzer.

Are you interested in Electrolyzer development and testing, or do you want to find out what Power-2-Hydrogen might bring to your company, please contact Yvonne van Delft.

Share this page: