OUTFOX – Optimized Up-scaled technology for the next generation solid oxide electrolysis

20-09-2023

VoltaChem and its founding partner TNO launched in February 2023, the 4-years European project OUTFOX in collaboration with Elcogen AS, Elcogen OY, Convion, VTT, POLIMI, Fondazione Politecnico di Milano, Shell and LINQ, to accelerate the deployment of the Solid Oxide Electrolysis (SOEL) technology for industrial production of green hydrogen. Through this project, a scale-up SOEL stack module toward 80kW scale is aimed to prepare SOEL for industrial scale systems of 100 MW with a low hydrogen cost and applicability to mass manufacturing lines.

VoltaChem and its founding partner TNO launched in February 2023, the 4-years European project OUTFOX in collaboration with Elcogen AS, Elcogen OY, Convion, VTT, POLIMI, Fondazione Politecnico di Milano, Shell and LINQ, to accelerate the deployment of the Solid Oxide Electrolysis (SOEL) technology for industrial production of green hydrogen. Through this project, a scale-up SOEL stack module toward 80kW scale is aimed to prepare SOEL for industrial scale systems of 100 MW with a low hydrogen cost and applicability to mass manufacturing lines.

Toward industrial scale of green- hydrogen production

With hydrogen’s potential to efficiently decarbonize key industrial sectors and energy generation firmly established, the need for sustainable and large-scale production solutions is more urgent than ever. Due to its unparalleled conversion efficiency when compared to other green hydrogen production methods, solid oxide electrolysis (SOEL) has the ability to be a winning solution for sustainably delivering hydrogen at the needed scale. However, current state-of-the-art SOEL systems are not capable of producing hydrogen at the necessary rate and cost, nor are they compatible with economical manufacturing processes that can produce electrochemical cells at the required scale to accomplish full decarbonization of relevant sectors.

OUTFOX ambition

The main aim of OUTFOX is to remove scale as limiting factor in the deployment of SOEL technologies, while proving their potential to become the preferred option for green hydrogen production. By combining experimental results up to 80 kW scales with identification of optimal cell and system designs, OUTFOX will prepare SOEL for industrial scale systems of 100+ MW with an LCOH as low as €2.7/kg hydrogen and applicability to mass manufacturing lines.

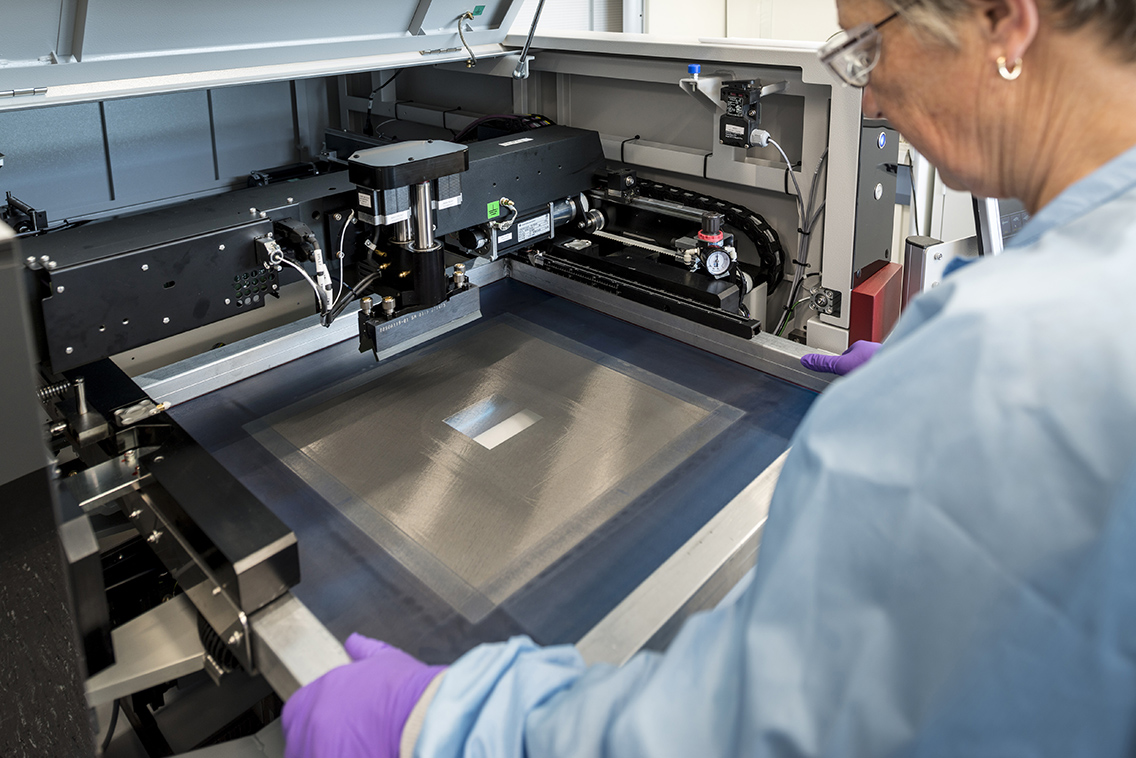

The industrially-driven OUTFOX consortium will combine expertise on cell, stack and module development, manufacturing, and full system evaluation to advance the maturity of SOEL and contribute to the targets of the Clean Hydrogen JU SRIA. OUTFOX will achieve current densities of at least 0.85 A/cm2 through the use of cells with 25% less thickness than current high volume state-of-the-art, improving sustainability through reducing total materials requirements. Scale-up will be approached from two sides: (1) development and validation of cells with geometric areas up to 800 cm2 that are compatible with at-scale manufacturing techniques, and (2) validation of optimized design concepts with increased numbers of stacks per module. The partners will validate high current density operation with reference scale (144 cm2), industrial scale (>300 cm2) and next-generation cells (900 cm2) in single repeating units, short stacks of 15 cells, and 80 kW prototype systems, leading to more than 10,000 hours of SOEL operation.

Two separate 80 kW testing campaigns with two different stack configurations and a total of more than 4000 operating hours, to be tested onsite at the Shell facilities in Amsterdam, will go beyond the scope of the call text to provide a comprehensive validation of the OUTFOX technology, thus providing key data for design of a full scale 100+ MW SOEL system, including the module configuration and all balance of plant requirements, and preparing the technology for a multi-MW demonstration following the project end. This project is funded by the Clean Hydrogen Partnership .

The kick-off meeting took place in Petten and Alkmaar on 27th and 28th of February.

For more details visit the website of OUTFOX here.

Share this page: