TNO and Powall sign license agreement on low-iridium catalyst powders for PEM electrolysis

25-09-2025

With the signing of a license agreement, TNO and the Delft-based company Powall have formally agreed to commercialise their shared intellectual property on iridium-containing catalyst powders that can revolutionise PEM electrolysis. It is a significant milestone in a joint development that started five years ago to combine TNO’s expertise on powder support materials with Powall’s technology for depositing iridium. The striking result paves the way to a highly efficient Catalyst Coated Membrane (CCM) that contains a minimal amount of iridium.

With the signing of a license agreement, TNO and the Delft-based company Powall have formally agreed to commercialise their shared intellectual property on iridium-containing catalyst powders that can revolutionise PEM electrolysis. It is a significant milestone in a joint development that started five years ago to combine TNO’s expertise on powder support materials with Powall’s technology for depositing iridium. The striking result paves the way to a highly efficient Catalyst Coated Membrane (CCM) that contains a minimal amount of iridium.

The license allows Powall to exclusively produce and market the innovative low-iridium catalysts. When applied in the next generation of anode CCMs in PEM electrolysers for hydrogen production, significant cost reductions can potentially be achieved. According to Powall’s Chief Technology Officer Sébastien Moitzheim, “the combination of the TNO powder particle with our process for iridium loading has proven to be so successful that we see clear commercial potential”.Martijn de Graaff, Program Director Power-2-X at TNO VoltaChem adds: “We’re proud to partner with Powall and contribute to improving green hydrogen production technologies through this promising Dutch innovation.”

An appealing process for catalyst deposition

The collaboration started in the early 2020’s when TNO proposed a lesser known powder as a carrier material for electrochemical catalysts. The material was predicted to combine a great stability, even in a highly oxidative environment, with good electrical conductivity. For their use as a CCM catalyst, they needed to be loaded with iridium oxide. The main challenge here was to use as little iridium as possible. Being a platinum group material, it not only is quite costly, but it is also a critical raw material with the associated negative geopolitical aspects.

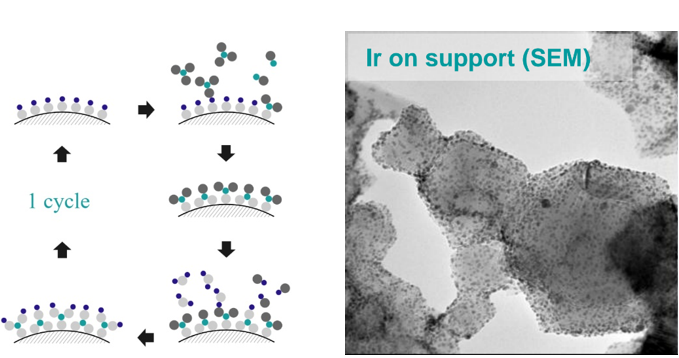

TNO turned to Powall because the company had developed a unique and scalable gas-phase atomic layer deposition process for coating powder particles. Featuring a solvent-free, highly controllable deposition of active monolayers, its potential for producing PEM catalysts looked very appealing. This was investigated in the MIGHTIER project, which delivered very promising results. Powall developed a process for not only depositing Ir-oxide onto this powder, but also for controlling the morphology and composition of the Ir-based coatings.

Applying the novel catalyst powder in an actual CCM revealed the potential to lower the iridium content to around 0.1 mg/cm2 - which constitutes a twentyfold reduction compared to current CCMs. Rigorous testing in an electrolyser cell in the TNO Faraday Lab, demonstrated that even at such low iridium content, a high hydrogen output could be realised. Moitzheim: “The good performance in a thousand-hour test really gave us confidence and prompted us to file for a patent.” He underpins that the combination of both the particle and the iridium loading yielded the success. “That's what we patented, and that's what the license agreement is about. It allows us at Powall to now exclusively produce and commercialize the catalyst particles for use in electrolysis.”

More work to be done

Although Moitzheim is quite optimistic about the potential, he stresses that more work needs to be done. “We’re preparing to scale up and engage with industry partners to explore the market potential.” For one thing, samples have been produced in gram-sized batches, but this needs to be increased: “When scaling up, we need to maintain a high deposition yield to avoid the loss of the precious iridium in our own process. That’s what we are working on now.”

Another development effort is in manufacturing the CCM using the catalyst powders. This goes by means of a colloid, an ‘ink’, containing the powder particles. The formulation and application still requires work, which is the focus of the recently kicked project ALIVE where TNO and Powall continue their collaboration. Moitzheim: “The idea is to offer to our customers not just the powder, but also the recipe for an optimally performant catalyst-coated membrane.”

Joint collaboration

Last but not least, Moitzheim realises that developing next-generation electrolysers is about more than just the catalyst coated membrane. While the novel catalyst powder can aid in boosting the hydrogen output per surface area of the CCM, all the other components of the electrolyser stack and beyond should be able to support this. “There's a lot of innovation that needs to go into electrolyzers if we really want to arrive at viable levels of hydrogen cost. For that we need joint collaboration of all component suppliers.”

Moitzheim is positive about what can be achieved in the cooperative atmosphere of the VoltaChem programme: “We have worked together very effectively and we've already come quite far. We had a lot of technical interaction with TNO, many iterations and many discussions about why things worked and why things didn't work. The testing of the CCMs under operating conditions at the TNO facilities was crucial, but also that the TNO scientists were good at analysing the results, sharing the information with us and engage in constructive discussion. Without that we wouldn’t have come this far.”

Do you want to know more? For more information please contact: Tara van Abkoude or Sébastien Moitzheim.

About the illustration

Schematic representation of Powall’s Atomic Layer Deposition technology. At left is depicted how a layer is deposited in multiple process steps, adding one molecular component at a time. The process can be carried out to achieve highly disperse IrOx on a support powder. Key features are superior control over nanocoating thickness, low waste generation and flexibility for a wide range of both coating and powder chemistries. Powall’s main focus is on developing the process for applications in the fields of batteries, electrolysers and fuel cells.

Share this page: