The materials issue of hydrogen production

31-10-2019 | P2Hydrogen

The importance of raw materials

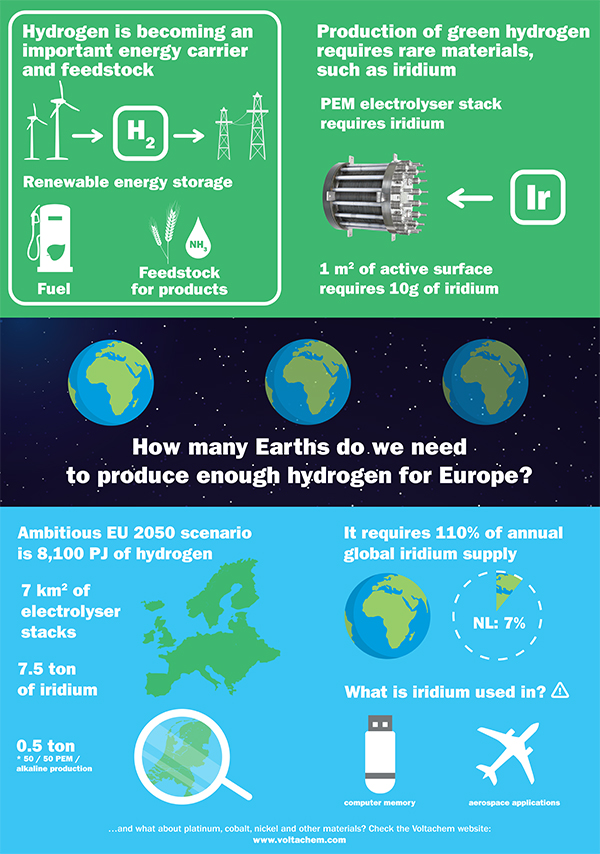

Producing adequate amounts of hydrogen is crucial to establishing a fully sustainable energy supply and producing sustainable chemical products. But the scale of the energy system can pose important problems. One important issue is the availability of raw materials for large-scale production of hydrogen through electrolysis. In a current Voltachem study, the scale of this problem is being quantified. In particular, iridium, platinum, and tantalum, cobalt and nickel are materials of concern.

Producing adequate amounts of hydrogen is crucial to establishing a fully sustainable energy supply and producing sustainable chemical products. But the scale of the energy system can pose important problems. One important issue is the availability of raw materials for large-scale production of hydrogen through electrolysis. In a current Voltachem study, the scale of this problem is being quantified. In particular, iridium, platinum, and tantalum, cobalt and nickel are materials of concern.

This so-called VoltaChem materials availability study was led by Anastasia Gavrilova, Energy Transition Consultant at TNO Strategic Business Analysis. She collaborated with colleagues from five different expertise groups. "This broad scope is quite unique for a relatively small project such as this", Gavrilova mentions. "But it is really necessary because the issue at hand is so comprehensive." At the beginning of September, all researchers joined in a three-day 'sprint' session. The focus was on PEM and Alkaline technologies, as these are proven technologies, already being used on a commercial scale. "In fact, material availability for hydrogen production is becoming a point of concern for many companies already", says Gavrilova. For each of the two technologies, the team identified the critical materials - based on multiple aspects such as resource availability, supply chain risks, geopolitical aspects as well as price volatility.

This led to the listing of five 'most critical' materials in green hydrogen production: iridium, platinum, tantalum, cobalt, and nickel. For each of these materials, the amount required for hydrogen production in the Netherlands alone was calculated, based on projections by the Institute for Sustainable Process Technology in their HyChain study. Gavrilova: "Of course those scenarios only give projections on what the future might look like since there are lots of uncertainties regarding the energy system in the coming decades. Yet, we have succeeded in presenting a range of numbers in terms of material requirements, and it allows us to see the scale of the problem for different levels of hydrogen demand."

This led to the listing of five 'most critical' materials in green hydrogen production: iridium, platinum, tantalum, cobalt, and nickel. For each of these materials, the amount required for hydrogen production in the Netherlands alone was calculated, based on projections by the Institute for Sustainable Process Technology in their HyChain study. Gavrilova: "Of course those scenarios only give projections on what the future might look like since there are lots of uncertainties regarding the energy system in the coming decades. Yet, we have succeeded in presenting a range of numbers in terms of material requirements, and it allows us to see the scale of the problem for different levels of hydrogen demand."

Defining the extent of the problem

"As an example let's look at iridium", Gavrilova says. "Since it is a well-known rare element, its identification as a critical material might not come as a surprise. However, although the industry recognizes the issue, there's little sense of its extent. That's why we have set out to provide the figures that define the scope of the problem. We have found that in a scenario of high hydrogen demand, Europe alone would need about 110% of the world’s annual iridium supply for the production and service of PEM electrolyzers. For the Dutch economy, this translates into 7% of iridium produced globally. Moreover, if we look at the most ambitious hydrogen scenarios in the Hychain study, the Netherlands itself might require a remarkable 30%. And these figures would double if PEM were to be the only hydrogen-generating technology used."

The obvious conclusion is that in the development of PEM electrolyzers it is paramount to reduce the need for iridium and other critical materials. That is already an important aspect of the VoltaChem shared innovation program. "Prolonging the lifetime of PEM electrolyzer stacks can also be part of the solution", Gavrilova adds, "as is the design for recycling, so that a larger share of the iridium can be reused." VoltaChem is already looking for producers and recycling companies for joint projects in this field. It concerns not only iridium but also other critical raw materials.

Raise awareness and develop alternatives

Gavrilova wouldn't go so far as to conclude that developing electrolysis based on iridium is a dead end. "There are still substantial changes and improvements to the PEM technology that we can make, but we should also develop alternatives of course. What we have done in this study is testing and quantifying the feasibility of electrolysis technologies from the materials availability perspective. I would say, the results demonstrate how crucial it is to raise awareness about the scale of the problem, find ways to reduce the amount of iridium used, focus on recycling, and work on alternative technologies."

Apart from iridium, materials such as tantalum and platinum were also classified as critical. “We found that for European hydrogen demand in 2050 we would require more than 30% of global annual tantalum supply and about 25% of that of platinum. The latter is mostly used in Alkaline technology, which highlights the fact that no technology is a silver bullet when it comes to material requirements says Gavrilova.

Gavrilova adds that studies such as these can be very valuable in the early phases of technology development. "It is important to appreciate the complexity of the issue right from the start. It's great to develop technology, but it has to be feasible with respect to raw materials availability. I think it is very worthwhile to screen for aspects of materials available when defining the technology of choice. To avoid that when a technology is maturing, availability issues come as a surprise."

Is this of interest to you?

Do you want to identify these and other potential bottlenecks in the development of electrification technology? Then join the VoltaChem Community or participate in one of the Power-2-Integrate projects.

For more information contact our Power-2-Integrate program manager Monique Rijkers.

Share this page: