High Temperature Electrolysis

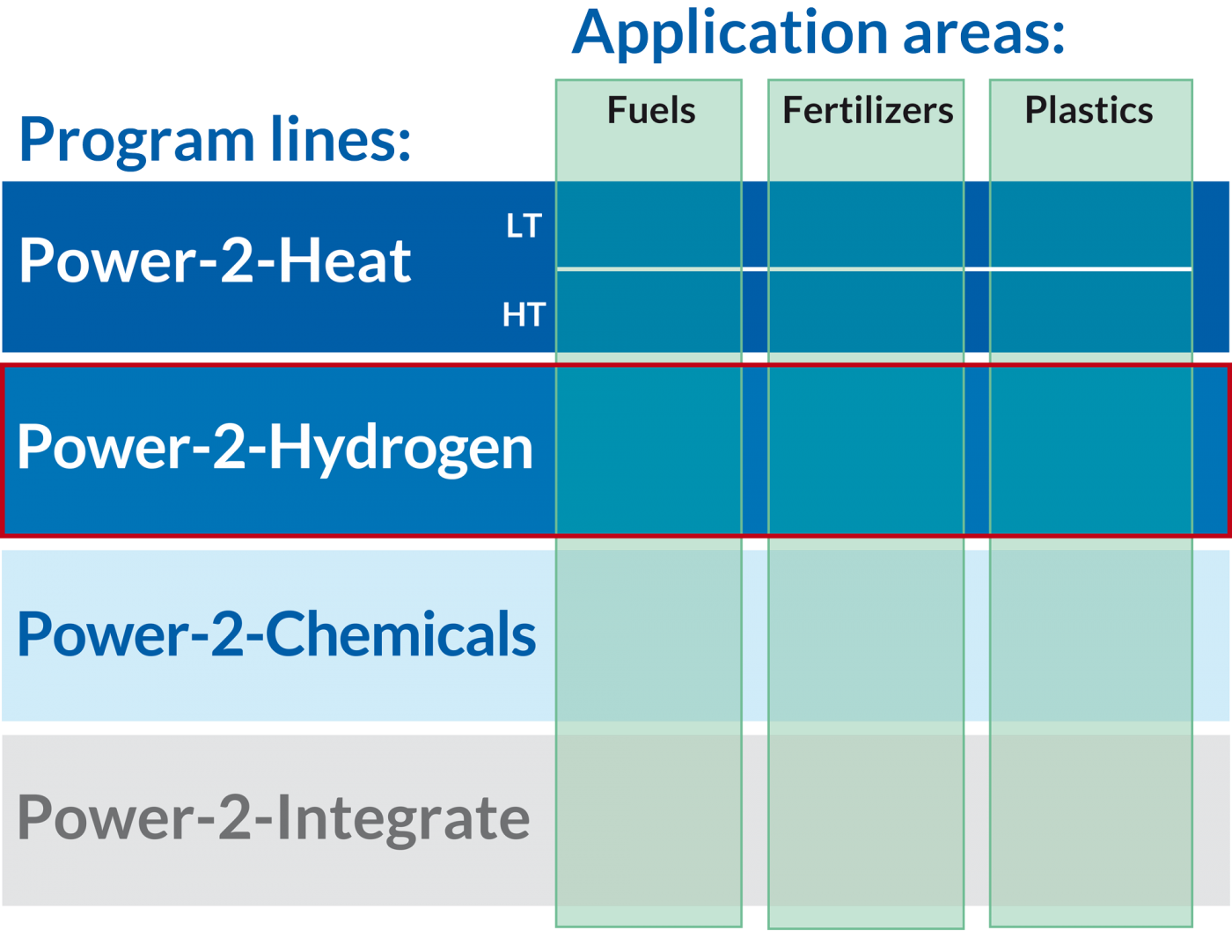

Running Projects | Power-2-Hydrogen

Core project partners

TNO,

Milestones

HT reference cell: November 2018

Lab-scale test unit built: December 2018

Contact person

Yvonne van Delft

Email

Context

The Solid Oxide Electrolyser (SOE) is mainly seen as a technology for industrial hydrogen production because of its high efficiency. Additionally, it offers opportunities for (heat) process integration with chemical processes. In addition to hydrogen production, the technology offers the possibility of reducing CO2 to carbon monoxide and valorizing syngas via co-electrolysis towards valuable chemical building clocks. The most important technological challenge in the development of SOE is to achieve sufficient service life (>80,000 hours). Increasing the power level is also vital for application at an industrial scale.

Objective

The main development objectives for SOE are lifetime extension, cost reduction and scaling up of the cells, i.e. increase their power level. To take steps in this direction, the current project aims to realize a SOE cell manufacturing line to contribute to the scale-up of fabrication and the individual cells. To be able to monitor lifespan, a reference SOE cell will be developed together with test infrastructure for longterm testing. A model is developed to better understand the degradation process and in turn increase SOE cells lifespan.

Deliverables

- Reference SOE cell;

- Demonstration of a high temperature lab-scale test platform for SOE cells;

- Model for modelling mass and ion transport in an electrolyser.

View Running Projects overview

Share this page: