Electrolysers: opportunities for the high-tech manufacturing industry

21-03-2023

Electrolysers: opportunities for the high-tech manufacturing industry

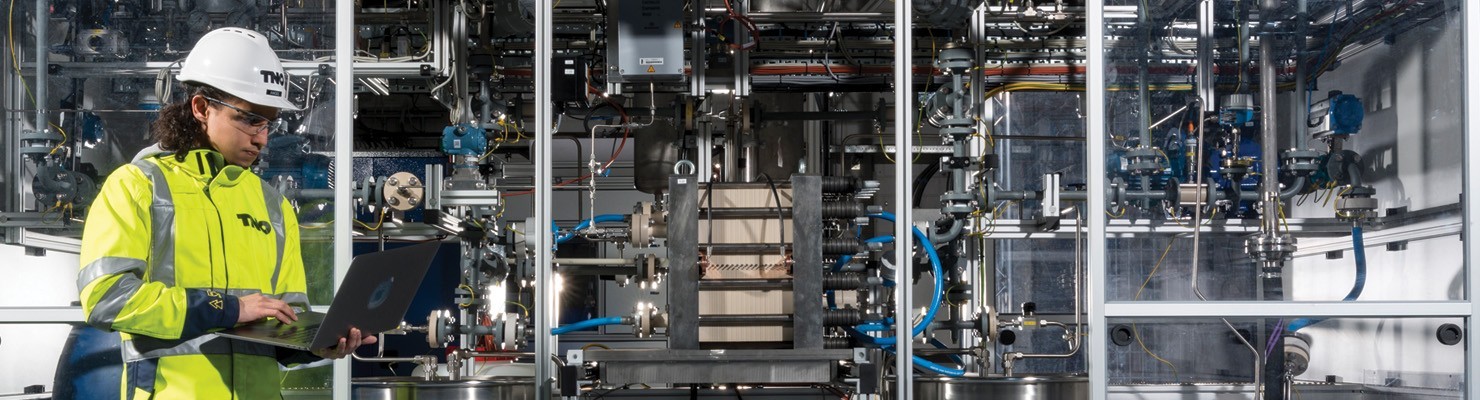

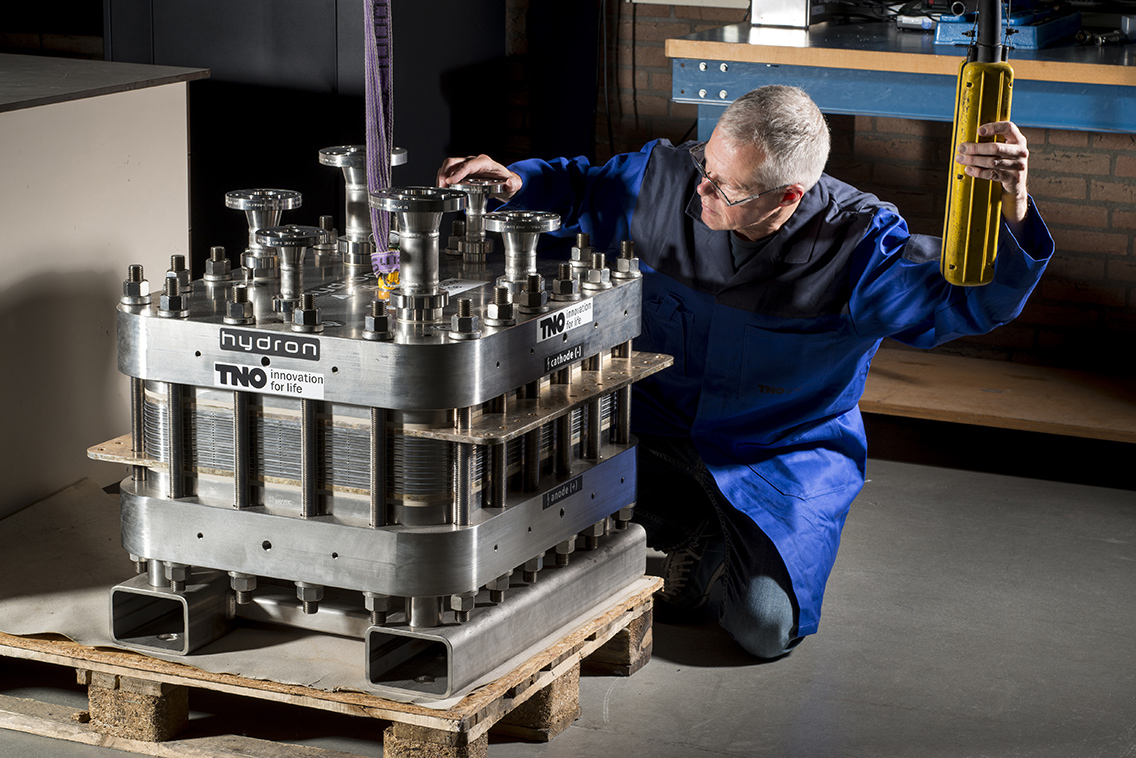

Currently, available electrolysis technologies and electrolyser manufacturing capacity are not yet fit to match the expected demand. To meet the energy transition challenge, manufacturing capacity of electrolysers has to scale up while simultaneously improving the design of the technology on a fundamental level, from its basic materials, to components, to entire system architecture.

VoltaChem has developed a discussion paper that illustrates how the challenge of rapid upscaling and improving electrolysers can be addressed by using high-tech manufacturing technologies as currently applied for the production of thin-film electronics.

Although the scope is limited to the case of so-called Proton Exchange Membrane (PEM) water electrolysers, many of the discussed principles are equally applicable to the alternative technologies, which are Solid Oxide Electrolysis (SOE), Anion Exchange Membrane (AEM) and Alkaline Water Electrolysis (AWE). Or even electrochemical conversion of biobased feedstock or CO2.

The discussion paper was made possible by VoltaChem, TNO, TNO in Holst Centre, Elektrolyser Makersplatform NL. We believe that it is the alignment of productive efforts, in research, development and upscaling, throughout the manufacturing supply chain that will provide the real and lasting opportunities that are needed to upscale improved electrolysis technologies.

Downloads

Share this page: