‘When electrons power molecules’ congress; shows readiness for the next level in electrification!

09-01-2019 | Event report

On December 13th, 2018 an interesting international blend of participants of the chemical industry, energy sector and technology suppliers like researchers, business & site managers, R&D managers, business developers, technical suppliers, and policymakers joined the Voltachem Annual Event at the Industry & Energy Congress: ‘When Electrons Power Molecules'. This event - in cooperation with Industrielinqs and FME - offered a program built around next-generation industrial electrification, needed to reduce the carbon footprint of the chemical industry. It showed, the industry is ready for the next step.

On December 13th, 2018 an interesting international blend of participants of the chemical industry, energy sector and technology suppliers like researchers, business & site managers, R&D managers, business developers, technical suppliers, and policymakers joined the Voltachem Annual Event at the Industry & Energy Congress: ‘When Electrons Power Molecules'. This event - in cooperation with Industrielinqs and FME - offered a program built around next-generation industrial electrification, needed to reduce the carbon footprint of the chemical industry. It showed, the industry is ready for the next step.

Why

To meet the European climate challenges and goals of the Paris Agreement, new ways of collaboration are needed. Fences between the heavy process industry and energy sector have to be lowered. First steps have already been taken. New energy saving processes have been implemented and advanced bio routes have been developed. And yet another, more sustainable synergy is rising… 'when electrons meet molecules'. To grasp this opportunity, new value chains have to be developed, cutting through multiple sectors.

‘Our goal is to make connections,' Says Martijn de Graaff, program- and business development manager of the Open Shared Innovation Program VoltaChem and one of the visionary frontrunners in accelerating industrial electrification. On such a congress day you reach a large group of people in many different fields. They know what's going on and what the trends are, but with such a congress you can offer an overview, have in-depth discussions, and at the same time fulfill a network function. People in the ecosystem must be able to find each other. For our VoltaChem program, this is crucial. That why we decided this year to embed our 4th annual event in this joined Industry & Energy Congress.

‘Our goal is to make connections,' Says Martijn de Graaff, program- and business development manager of the Open Shared Innovation Program VoltaChem and one of the visionary frontrunners in accelerating industrial electrification. On such a congress day you reach a large group of people in many different fields. They know what's going on and what the trends are, but with such a congress you can offer an overview, have in-depth discussions, and at the same time fulfill a network function. People in the ecosystem must be able to find each other. For our VoltaChem program, this is crucial. That why we decided this year to embed our 4th annual event in this joined Industry & Energy Congress.

Mark Williams of Sabic: "We need an awful lot of innovation.”

The plenary morning program included a keynote by vice president Mark Williams of event partner Sabic Europe, and short talks by Chemelot director Robert Claasen, chemical researcher Bert Weckhuysen of Utrecht University and Executive Project Sponsor Johan Cnossen of ThyssenKrupp.

Williams firmly set his company's goals and the urgency of the transition: by 2050, the world will need 35 percent more food, 50 percent more energy and 40 percent more water, while at the same time reducing CO2 emissions by 80 percent. A huge challenge for a planet that is already struggling.

And that challenge is particularly true for the chemical sector. Although the Sabic's new cracker Olefins-4 at Chemelot is 'probably the most efficient in Europe', it still accounts for 2 percent of Dutch CO2 emissions. But that could change with biomass or eventually plastics as feedstock. Of course, economic considerations determine which of these paths are really feasible, so the ball is also in the court of external factors such as politics. Anyway, Williams concluded, 'We need an awful lot of innovation'.

And that challenge is particularly true for the chemical sector. Although the Sabic's new cracker Olefins-4 at Chemelot is 'probably the most efficient in Europe', it still accounts for 2 percent of Dutch CO2 emissions. But that could change with biomass or eventually plastics as feedstock. Of course, economic considerations determine which of these paths are really feasible, so the ball is also in the court of external factors such as politics. Anyway, Williams concluded, 'We need an awful lot of innovation'.

Robert Claasen of Chemelot

Chemelot director Robert Claasen once again sharpened the urgency of the change. We are the only chemical cluster in the Netherlands that is not located by the sea,' said Claasen, 'Not yet'.: “This would not be the first major change.”

For, formerly the exclusive domain of DSM, this would not be the first major change. We have already switched from coal to gas, and from single to multi-user,' says Claasen. The switch to a sustainable chemical and energy sector is not only about new raw materials such as recycled plastic, but also about developing new chemical processes.

For, formerly the exclusive domain of DSM, this would not be the first major change. We have already switched from coal to gas, and from single to multi-user,' says Claasen. The switch to a sustainable chemical and energy sector is not only about new raw materials such as recycled plastic, but also about developing new chemical processes.

The Brightlands campus, the location of the meeting, was also set up to develop and research this. Claasen: “We have to coordinate and plan which matters we give priority to. Chemelot is looking for companies that fit the intended changes, but they must also fit into the value chain, or contribute to new value chains.”

Professor of inorganic chemistry Bert Weckhuysen of Utrecht University stressed the role of research, and also the fact that the changes must be fully implemented by the younger generation. “I think it is good that students have come here too.”

Johan Cnossen of ThyssenKrupp in Germany described a concrete project, who spoke about the pilot plant in Duisburg, where hydrogen is now produced with a 2 MW electrolysis installation, with the prospect of further scaling up. Cnossen: “The question is whether hydrogen can ultimately be produced that can compete with hydrogen from natural gas. We believe that this can be done well.

Johan Cnossen of ThyssenKrupp in Germany described a concrete project, who spoke about the pilot plant in Duisburg, where hydrogen is now produced with a 2 MW electrolysis installation, with the prospect of further scaling up. Cnossen: “The question is whether hydrogen can ultimately be produced that can compete with hydrogen from natural gas. We believe that this can be done well.

Industrial Energy Enlightenmentz award, and the winner is ...

Part of the plenary program was the Industrial Energy Enlightenmentz election, intended to inspire the audience and boost the companies in applying promising innovations and processes.

The three competing pitches were given by:

Philip de Goey of Metalot, presented an innovation platform with a project to switch from coal-fired power stations to the combustion of re-usable iron powder instead of coal.

The research group of prof. Fokko Mulder at TU Delft developed The Battolyzer; it combines the power storage of batteries with the hydrogen production capacity of an electrolysis installation.

Bernd van den Bossche from the Belgian startup Qpinch showed the audience how they use the principles of heat conversion from living cells to upgrade industrial heat to 75 degrees but 230 degrees Celsius.

A combination of internet voting, public voting, and a professional jury declared at the end of the day the Battolyzer as the winner of the Industrial Energy Enlightenmentz 2018.

“The design had already been used by Thomas Edison before”, said initiator Fokko Mulder. “The problem was that the battery, when fully charged, started to produce hydrogen.” Mulder decided to make this bug a feature. “The Battolyzer combines short-term electricity storage with hydrogen production once charged. Bringing best of both worlds together.”

“The design had already been used by Thomas Edison before”, said initiator Fokko Mulder. “The problem was that the battery, when fully charged, started to produce hydrogen.” Mulder decided to make this bug a feature. “The Battolyzer combines short-term electricity storage with hydrogen production once charged. Bringing best of both worlds together.”

9 themes, 27 substantive breakout-sessions, 3 site tours

In the afternoon 27 breakout sessions were held on various themes: Power-to-Integrate, Power-to-Heat, Power-to-Hydrogen, Power-to-Chemicals, CO2 as a raw material (CCU) and Impact Innovations.

Topics ranged from highly technical topics such as the production of solar fuels with the help of electrocatalysis and electric crackers for the chemical reduction of CO2 to more business considerations on business cases, time-to-market and Technology Readiness Levels and overarching workshops on infrastructure and legislation, long-term scenarios, scaling up and integration of chemical processes. Visitors could also take a bus tour of the various installations on the extensive Chemelot site. All presentations can be downloaded here.

Power-to- Hydrogen: state of the art in Hydrogen electrolysis

In the Power-to-Hydrogen theme sessions, Arend Groot- technical lead in Power-2-Hydrogen VoltaChem program - compared the capital and operating costs of electrolysis with the help of a triangular diagram in which an optimum must be chosen between efficiency, costs and lifetime of the installation. In addition, the number of hours that the installation runs per year are important for the final operating costs. This is higher for an installation that runs permanently than for one with an electrolysis installation that absorbs the peaks of a fluctuating power supply.

In the Power-to-Hydrogen theme sessions, Arend Groot- technical lead in Power-2-Hydrogen VoltaChem program - compared the capital and operating costs of electrolysis with the help of a triangular diagram in which an optimum must be chosen between efficiency, costs and lifetime of the installation. In addition, the number of hours that the installation runs per year are important for the final operating costs. This is higher for an installation that runs permanently than for one with an electrolysis installation that absorbs the peaks of a fluctuating power supply.

Raymond Schmid of Norwegian company Nel Hydrogen told about the hundreds of smaller electrolysis installations in the world that already produce hydrogen commercially, including for a network of hydrogen filling stations in the US. Schmid: “We are committed to the hydrogen economy”, based on the expectation that electricity will fall in price in the future.

Power-2-Chemicals: Chemical reduction of CO2 to higher quality chemical

In one of the three Recap Sessions about events organized by Voltachem during 2018 the production of fuels from CO2, was discussed, and in a separate session a brainstorm on the ideal end product to be produced through electrochemical CO2 reduction.

Under the leadership of Klaas-Jan Schouten, program manager electrochemistry at Avantium and Anca Anastasopol, research scientist at TNO, a long list of candidate products was created in interaction with the participants on a flipchart, from sugars, kerosene and formic acid to syn-gas, the mixture of hydrogen and carbon monoxide, from which synthetic fuels can be made via the Fischer-Tropsch process.

Under the leadership of Klaas-Jan Schouten, program manager electrochemistry at Avantium and Anca Anastasopol, research scientist at TNO, a long list of candidate products was created in interaction with the participants on a flipchart, from sugars, kerosene and formic acid to syn-gas, the mixture of hydrogen and carbon monoxide, from which synthetic fuels can be made via the Fischer-Tropsch process.

The winner after discussion and voting was the intermediate product carbon monoxide, which is toxic but a broadly applicable chemical building block. The discussion got off to a good start, and I found the choice for carbon monoxide surprising,' said Schouten, as it is not directly marketable, "because it is toxic, you have to use it immediately in a process to make something else, so you will have to integrate such a process."

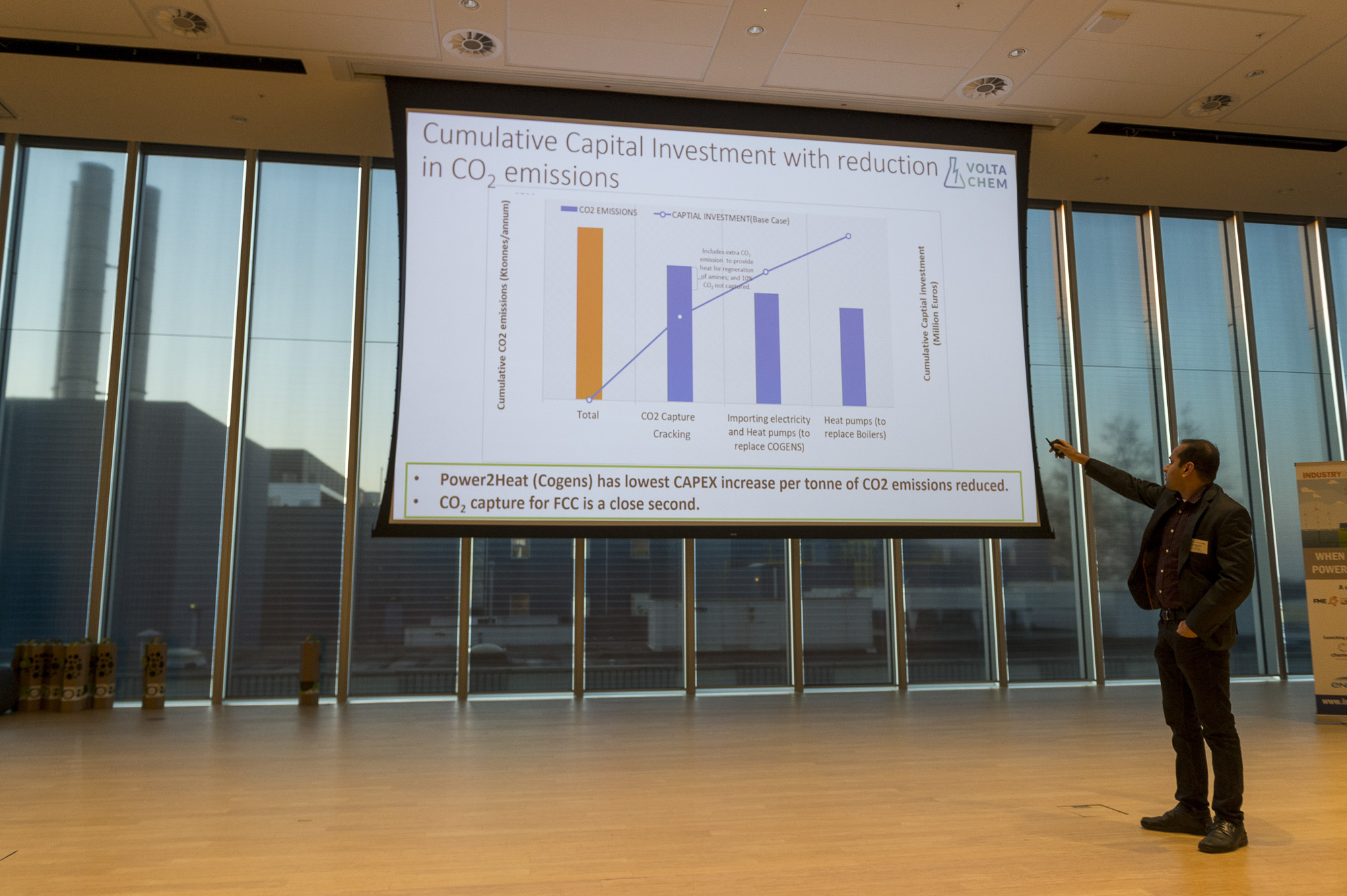

Power-to-Integrate: Analysis of CO2 reduction possibilities

In the third round of breakout sessions, under the theme Power-to-Integrate, Rajad Bharadwaj and Willem Frens of VoltaChem discussed an instrument that uses an extensive model of energy and material flows to map out how companies can save on their CO2 emissions and the economic impact of technological choices. Business development manager Frens: “We are looking for feedback from companies, but also from complete clusters such as Chemelot.”

In the third round of breakout sessions, under the theme Power-to-Integrate, Rajad Bharadwaj and Willem Frens of VoltaChem discussed an instrument that uses an extensive model of energy and material flows to map out how companies can save on their CO2 emissions and the economic impact of technological choices. Business development manager Frens: “We are looking for feedback from companies, but also from complete clusters such as Chemelot.”

Quiz: True or pure nonsense? Car captures its own CO2

After the breakout sessions, the plenary wrap-ups of the day and Energy Enlightmentz announcement, the social part was introduced with a cap-on-cap-off quiz, in which the ready knowledge of the public was put to the test. Surprisingly was that only a minority of the public was aware that Saudi Aramco is working on a passenger car, in which the CO 2 from the exhaust gases is captured and converted into a solid form, which can then be delivered to petrol stations. The car turns out to be a much-debated topic during the networking drink that followed.

"A very useful day”, says Erwin Giling, program manager Power-2-Chemicals at TNO. “I see that experts from the world of advice and industry, chemistry and energy meet here. And I've seen good discussions. Typical of large transitions like this are chicken egg problems, Gilling thinks: 'green hydrogen is not yet available on a large scale. What you get in the meantime is ordinary hydrogen by reducing natural gas, which is not yet clean, but you do prepare for the transition.” Choosing the right processes remains difficult, Giling believes. “I don't think the silver bullet exists, but I've seen a lot of new ideas, and I think you have to do a lot of things to see what works.”

"A very useful day”, says Erwin Giling, program manager Power-2-Chemicals at TNO. “I see that experts from the world of advice and industry, chemistry and energy meet here. And I've seen good discussions. Typical of large transitions like this are chicken egg problems, Gilling thinks: 'green hydrogen is not yet available on a large scale. What you get in the meantime is ordinary hydrogen by reducing natural gas, which is not yet clean, but you do prepare for the transition.” Choosing the right processes remains difficult, Giling believes. “I don't think the silver bullet exists, but I've seen a lot of new ideas, and I think you have to do a lot of things to see what works.”

Making great steps forward!

“We have grown enormously in the number of participants, but also in the enthusiasm and readiness”, says Martijn de Graaff, program- and business manager of VoltaChem. At our previous annual events and meetings, the discussion was often: the business case is not coming to an end. But now we're talking about the circumstances in which it does manage: at what energy price, at what fluctuations in electricity production, and at what CO2 price. That is a great step forward. We therefore strongly believe that investments in this subject will increase in the coming years. And that is also necessary because the CO2 reduction targets are not tender.

Want to know more about our VoltaChem program and our projects?

The presentation of the VoltaChem Annual event breakout session are available and can be downloaded here. Are you interested in our more specific project results or need more in-depth information about the VoltaChem program lines? Please contact our business manager Willem Frens. If you want to know more about our community and discuss your options, you can contact our community manager Monique Rijkers

VoltaChem projects

In this broadsheet VoltaChem in Action, you'll find examples of our (inter)national projects within our Power-to-Heat, Power-to-Hydrogen, Power-to-Chemicals, and Power-to-Integrate program lines.

Share this page: