First Community of Practice meeting in Power-2-Chemicals attracts international audience

04-08-2019 | Event report | P2Chemicals

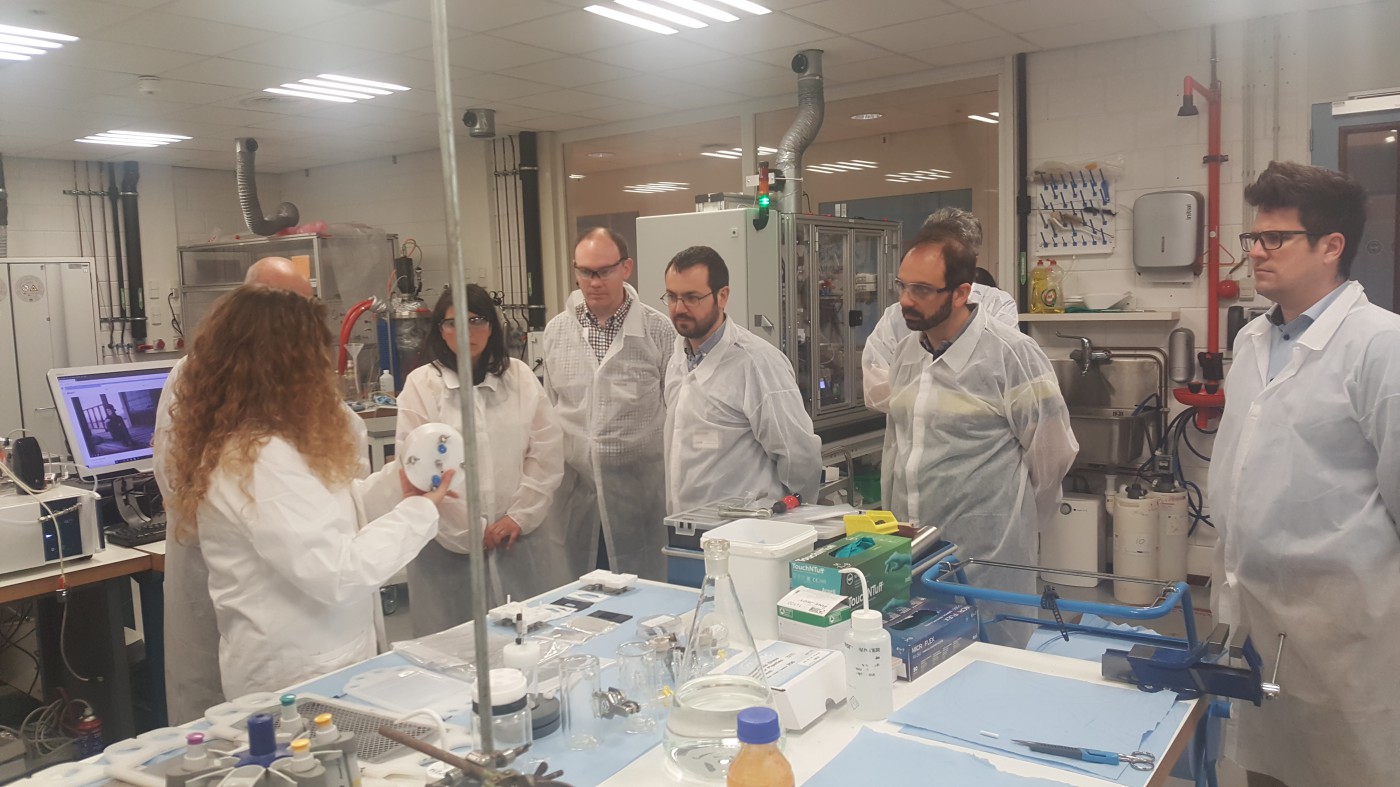

At the first VoltaChem Community of Practice (CoP) meeting on Power-2-Chemicals, held 17 June at the TNO premises in Delft, an international audience was brought up-to-date on the 'Opportunities of using electrochemistry in chemical production'. Hosted by Prof. Earl Goetheer, VoltaChem's technical lead in Power-2-Chemicals, the meeting was informative and sparked a lively debate.

At the first VoltaChem Community of Practice (CoP) meeting on Power-2-Chemicals, held 17 June at the TNO premises in Delft, an international audience was brought up-to-date on the 'Opportunities of using electrochemistry in chemical production'. Hosted by Prof. Earl Goetheer, VoltaChem's technical lead in Power-2-Chemicals, the meeting was informative and sparked a lively debate.

The participants were for the larger part from industry - petrochemical companies, engineering firms, start-ups. They had traveled from countries such as Finland, Ireland, Germany, and Belgium to Delft. "As far as I know, VoltaChem is the only European effort building such a community and providing access to research and technology in this field", one of them motivated his presence.

During the wrap-up, the meeting was considered interesting and useful, bringing all participants to the same level regarding the developments in Power-2-Chemicals (P2C). Already participants expressed the need for more detailed sessions regarding specific aspects, such as equipment. Goetheer suggested future meetings on specific showcases, zooming in on specific parts of the value chain. These meetings may well be in the form of webinars or other online formats, preventing the need to travel.

Broad portfolio

VoltaChem’s Communities of Practice are industrial interest groups interested in obtaining more technological insight into electrification. They also serve to connect the VoltaChem proposition to the needs of the community, possibly resulting in new VoltaChem projects. At the Power-2-Chemicals meeting, the broad portfolio of electrochemical reactions within VoltaChem was presented.

In his introduction*, Earl Goetheer, who is also a professor of Electrochemical Transformation of CO2 at the Delft University of Technology, explained the advantages of electrosynthesis in comparison to existing synthetic procedures.

Powering chemical conversions using electrons instead of heat can result in ambient process conditions, higher selectivities and elevated efficiencies. It also satisfies at least 9 of the 12 postulates of sustainable or green chemistry.

Powering chemical conversions using electrons instead of heat can result in ambient process conditions, higher selectivities and elevated efficiencies. It also satisfies at least 9 of the 12 postulates of sustainable or green chemistry.

Although using electricity in chemistry goes back a long time, it has remained in the domain of academia - where the main output consists of scientific papers rather than industrially produced chemical products. The need to enhance the sustainability of the chemical industry now results in a renaissance for electrochemistry, according to Goetheer. "It now is all about bringing electrosynthesis from the laboratory to the industry, which also means integrating it with downstream processing."

Lessons learned

The focus of the VoltaChem efforts is on minimizing the risks of this development, and Goetheer is convinced that success will be its part. Lessons learned from the field of heterogeneous catalysis, where over the years a fruitful relation between academia and industry has been established, contribute to his confidence.

He continued with an overview of electrolysis, its principles, and its pitfalls. In a rapid succession of sheets, he pointed to the crucial aspects of the electron transfer process in surface-based chemistry, including the surface of the electrodes and their adsorption characteristics regarding relevant intermediates and products. He took his audience from the scale of nanometres to that of millimeters and ultimately of meters, which all have to be taken into account when ultimately designing a viable process.

To Goetheer, the concept of paired electrolysis is one of the main future opportunities. It entails the production of valuable products at both electrodes - contrary to common industrial electrochemical processes, where a counter electrode mainly serves as a means to close the electrical circuit.

Developing optimization strategies

In the next presentation*, TNO's Amanda Garcia dove more deeply in the subject of organic electrosynthesis. She presented the pros and the cons - the latter including, amongst others, the complex reaction mechanisms and the lack of a fundamental understanding thereof. At TNO, much effort is put in developing optimization strategies to scale up organic electrosynthesis towards practical application, ultimately using flow cells at high pressures. Again, paired electrolysis was presented as a promising concept. The second half of Garcia's presentation contained a concise overview of the 'TNO electrochemistry toolbox' concerning many chemical conversions (such as oxidation, C-C coupling, reductions, arylation reactions, amination, hydroformylation), starting from a broad range of possible feedstock (such as sugars, glycerol, furfural, levulinic acid, propanediol).

In the final presentation*, Roman Latsuzbaia provided a detailed view of a couple of successful cases in electrochemical process development in the field of biobased plastic monomers. One of those was the conversion of biomass-derived HMF (hydroxymethylfurfural) to FDCA (furane dicarboxylic acid), a building block for PEF bioplastic. Latsuzbaia reported 90-95% yield in a well-performing, efficient system. He gave a concise overview of the relevant parameters in electrosynthesis and how to perform research and development to work your way towards an optimum, ultimately resulting in the best design of reactor and electrodes. He explained the importance of an integrative approach in which aspects such as downstream processing and techno-economic analyses are integrated into the scale-up process and thus aid the decision-making process towards a viable outcome.

Insightful discussions

After the lunch break, the remainder of the meeting was devoted to a discussion led by Reinier Grimbergen, VoltaChem's business developer Power-2-Chemicals / specialties. The subjects were: Carbon capture and utilization - CO2 as a raw material for the future; and How to bridge the valley of death for specialties.

On the subject of CO2 capture and its electrochemical utilization, a British participant questioned its value in view of the need to reduce atmospheric carbon. In particular regarding the production of fuels - which upon burning would ultimately release the CO2 back in the atmosphere. On the other hand, producing high-value chemicals is nothing more than scratching the surface as this only effects the less than ten percent of the total production of oil. The carbon of the other 90% of the oil would still end up as CO2 in the atmosphere. Contrary to this point of view a German participant, working in a major oil company, pointed out that carbon capture and utilization is in particular worthwhile from a perspective of circularity rather than reducing atmospheric CO2 reduction. VoltaChem's Earl Goetheer made the remark that utilization of CO2 (or CO, for that matter) is especially worthwhile when working towards chemicals that retain the oxygen atoms. In his view, producing 'plain' hydrocarbons is not quite rational since stripping all the oxygen atoms requires large amounts of energy.

A producer of biobased chemicals brought in another point of view. Since deforestation associated with producing these 'green' chemicals is under the scrutiny of the public, the company is looking for other options to replace oil as a feedstock. Utilizing CO2 might be among those options. Earl Goetheer stressed the importance of sourcing CO2 from point sources rather than air capture, as the latter suffers from the very low CO2 concentration. Goetheer envisions combined capture-and-conversion facilities processing flue gas from, for instance, steel mills or cement factories.

Reducing waste as a driving force

In producing specialty chemicals by means of electrosynthesis using CO2 as a feedstock, closing the carbon cycle may be the conceptual driver. However, regarding the business case probably the prospect of reducing the amount of waste will be a more decisive driving force. Oil and chemical companies currently exploring the possibilities of electrosynthesis seem to be struggling with real-life data. As one of the participants put it: "There's plenty of textbook knowledge, but very few data from real-life processing". Often assumptions have to be made regarding the dilution of the product stream and its processing using separation and isolation procedures. As a result, a forecast of production costs can't be more than a rough estimate.

The role of start-up companies

Industrial implementation of electrosynthesis will probably depend on start-up companies. Established chemical industries lack proper expertise and infrastructure and therefore leave electrochemical development to others. But if promising innovative electrochemical technology has matured, it will see broad implementation throughout the industry, Goetheer expects. Even more so if 'green' and 'circular' technologies will really be considered value-adding. Currently, companies are willing to spend roughly 10% extra for sustainably produced chemicals. That percentage may rise in the (near) future, for instance under pressure of (EU) regulation.

Finally, an interesting concept was put forward by one of the workshop participants. Labeling chemicals with their 'CO2 share' might have a positive price effect, as customers might be willing to pay more depending on the amount of CO2 used in the chemicals.

Would you like to join our Community of Practice?

In view of the participants' positive experiences and their joint request for more knowledge exchange, we have decided to continue this Power-to-Chemicals Community of Practice. We expect to organize the next session this fall. If you like to join this new CoP group, please contact our business managers Power-to-Chemicals Reinier Grimbergen or Willem Frens. You can also start using this interest form.

The presentations given during this first CoP/Power-to-Chemicals meeting can be found here.

Share this page: