NextGenP2H2: paving the way for a full-scale Dutch PEM electrolyzer

22-07-2019 | New Project | P2Hydrogen

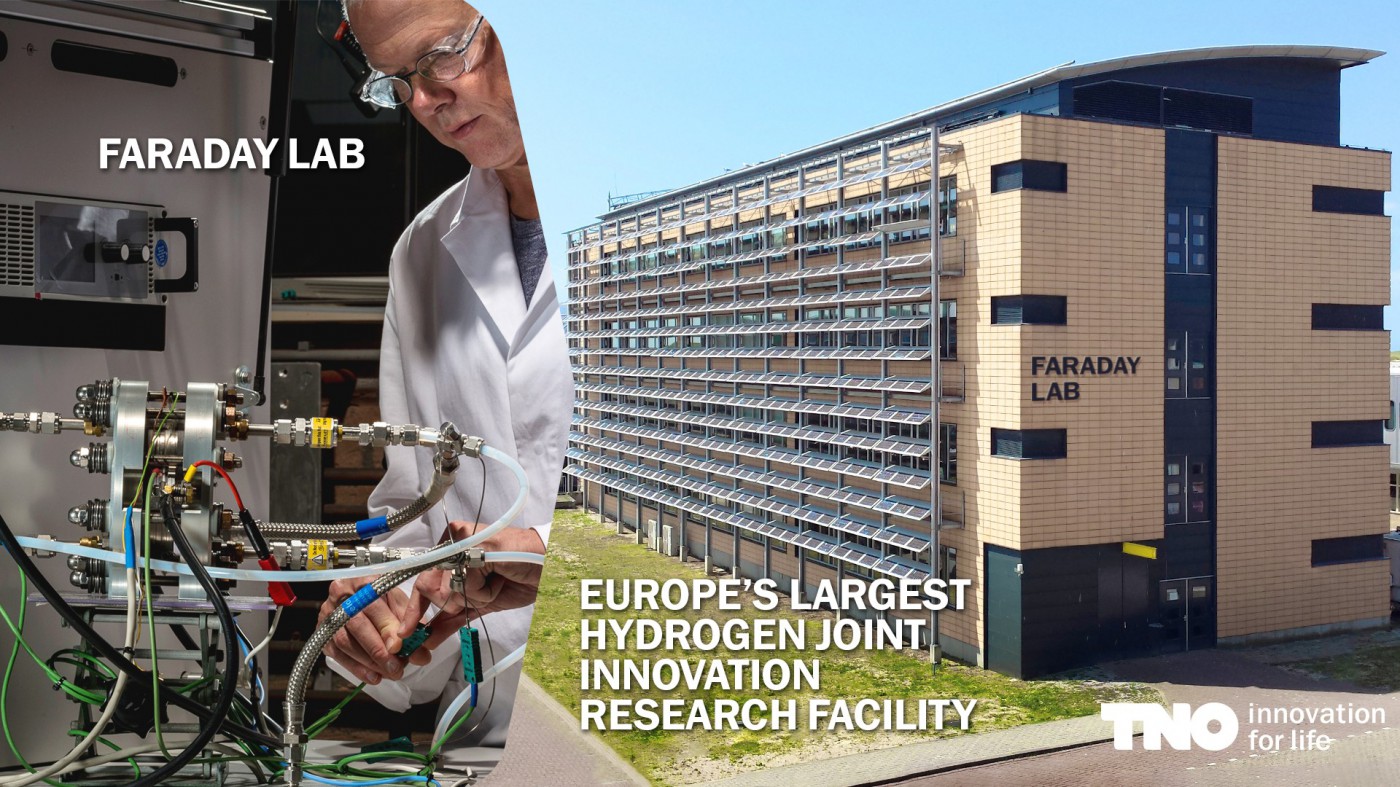

Friday 13 September the 50 kW PEM electrolyzer test system will be revealed and started up at the Faraday Lab in Petten. Within NextGenP2H2 project, the PEM technology will be optimized in view of low cost and high performance, thus paving the way for further development of a full-scale Dutch MW PEM electrolyzer.

Friday 13 September the 50 kW PEM electrolyzer test system will be revealed and started up at the Faraday Lab in Petten. Within NextGenP2H2 project, the PEM technology will be optimized in view of low cost and high performance, thus paving the way for further development of a full-scale Dutch MW PEM electrolyzer.

As a result of prior research and development at VoltaChem the 50 kW prototype PEM electrolyzer system has been installed at the brand new TNO Faraday Lab for research into electrochemistry. In NextGenP2H2 project, part of the Power-2-Hydrogen program line, this system will be thoroughly tested and optimized. A major goal is enhancing the performance of key components such as membranes, electrodes, and seals, thus prolonging the lifetime of the electrolyzer stack. Furthermore, the focus will be on further reducing the cost of PEM technology: a factor 2-5 is necessary to offer a competitive alternative to fossil-based H2 production.

The optimized NextGenP2H2 50kW system will thus combine low cost with high performance and manufacturability. The knowledge obtained will be used for the conceptual design of a full scale of 1 MW PEM electrolyzer. The project will also help to decide in which value chain this electrolyzer can be deployed, following the analysis of business cases for various Power-2-X applications.

Knowledge and infrastructure

The Faraday Lab of TNO in Petten builds on extensive knowledge and experience obtained in earlier long-running PEM fuel cell program that included work on reversible PEM fuel cell and electrolysis systems. At the Faraday Lab testing facilities, third party electrolyzer stacks and small-scale components can be tested and characterized aiming for cost efficiency and robustness. This will strengthen the competitiveness of Dutch industry in the field of electrolyzers, that is currently dominated by international manufacturers. Given the huge predicted growth in green hydrogen demand, great opportunities will arise in the electrolyzers market.

Consortium

To develop the 'future-ready' next generation of Dutch PEM electrolyzers, Voltachem joins forces with Hydron Energy (Noordwijkerhout) and Frames Energy Systems (Alphen aan den Rijn) in the 'first Dutch' consortium.

Hydron Energy is an innovative Dutch clean‐tech company that develops, manufactures and markets high performance & cost-effective PEM electrolyzer stacks. In the NEXTGENP2H2 project, Hydron Energy has optimized its 50 kWe stack platform on performance and cost. Furthermore, a conceptual design of a 1MW electrolyzer stack has been drafted.

Frames Energy Systems designs and constructs process installations for the global onshore and offshore oil- and gas industry. Frames will contribute to the extension of the industrial prototype to a test platform and the construction & commissioning of the 50kW test platform at the Faraday Laboratory. Next to that Frames will develop the scale-up design for the next phase, including site-specific requirements and a business case for the next phase.

As a follow-up, VoltaChem is already working on a 250kW PEM system to be tested at the Hydrohub test center in Groningen, where research and stress testing at MW scale will be performed as a stepping stone towards future GW scale production of sustainable hydrogen by the process industry. The Dutch Topsector Energy is supporting and co-funding this project.

Register to attend the kick-off

The NextGenP2H2 kick-off is part of the B2B matchmaking event 'Fueling the future with renewable gases', held 12-13 September in Alkmaar. More information can be found at the event site. Would you like to attend this two-days event, please sign up here (open until September 4, 2019).

If you only want to attend our opening/workshop event on September 13th, you can also use our sign-up form here at this agenda item on our site.

Share this page: