Huge opportunities for electrolyzer technology in future gigawatt green hydrogen market

24-03-2019 | Event report | P2Hydrogen

The choice for ECN∙TNO Petten was motivated by its expertise and research in water electrolysis technology and its ambition to become the European hub in this field. About three years ago the institute decided to revitalize its expertise that over the years had been mainly developed in fuel cell research. Last year it received substantial Dutch governmental funding for a brand-new Faraday Laboratory, to further develop electrolysis research and development.

The growing relevance of water electrolysis lies in its use for producing hydrogen from water using renewable electricity. This provides an option for the use of renewable electricity for the chemical industry and other sectors, and a means to balance future electricity distribution networks. There is quite a challenge here, for instance since the projected generation of wind energy at the North Sea will be at the scale of multiple gigawatts, whereas electrolyzer technology now features at the megawatt scale.

Bringing down the cost of hydrogen

Arend de Groot, technical lead of VoltaChems Power-2-Hydrogen program, outlined these and other challenges in his opening introduction presentation*. He underpinned the importance of electrolyzer cost reduction for achieving an acceptable price of hydrogen generation. This is even more important as electrolyzers running on renewable electricity will not be operating continuously. When they are used at a much lower capacity the capital cost weighs heavily on the exploitation.

Ultimately the cost of hydrogen is the result of a trade-off between cost, lifetime and efficiency of electrolyzers. The producers of electrolyzers (predominantly based abroad) are for the larger part focusing on optimization of their - proprietary - electrolyzer design. When it comes to reducing cost, they depend strongly on their suppliers. This supply chain, therefore, holds great opportunities for the high-tech industries - on the one hand regarding the electrolyzer itself (developing less expensive components that meet durability targets under the operating conditions) and on the other hand regarding the system as a whole (including, for instance, hydrogen handling and developing integrated systems).

Huge opportunities in green hydrogen

The latter was further elaborated by Gigi van Rhee of Stratelligence consultancy in her presentation* of the preliminary results of a study for the Netherlands Enterprise Agency RVO. It comprised an outlook on the broader hydrogen value chain and identification of the (future) market players in the different segments of the supply chain. According to Van Rhee opportunities will arise specifically for Dutch industry sectors such as the gas industry, the sensor industry, companies in coating and sealing, filtering and separation, and specialists in high-pressure technology.

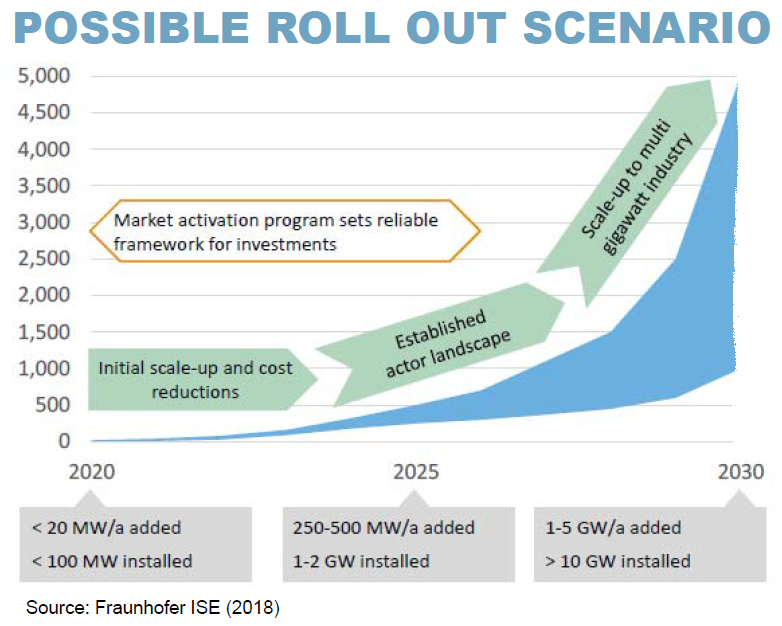

Earlier in the day, Lennart van der Burg, VoltaChem business developer Green Hydrogen, had already provided a 'stunning' outlook* on sales opportunities of tens of billions of Euros in 2030 for production and distribution of hydrogen in Europe alone.  Taking different scenarios into account he made it clear that hydrogen demand will be huge, and that in the foreseeable future technology for large scale water electrolysis will be in great demand. He provided an overview of current hydrogen initiatives in the provinces of Groningen and Zuid Holland, and mentioned some exciting European projects, amongst others in the steel industry.

Taking different scenarios into account he made it clear that hydrogen demand will be huge, and that in the foreseeable future technology for large scale water electrolysis will be in great demand. He provided an overview of current hydrogen initiatives in the provinces of Groningen and Zuid Holland, and mentioned some exciting European projects, amongst others in the steel industry.

However, in order to meet the potentially high future demand, Van der Burg stated, improvement of the electrolysis supply chain is an absolute prerequisite. He underpinned the importance of the VoltaChem workshop and the involvement of new companies.

Much to be improved in electrolyzer technology

Through VoltaChem, ECN∙TNO aims to provide to industry in-depth knowledge of the working of a PEM electrolyzer and of the degradation processes. ECN∙TNO researcher Paige Shirvanian provided a short but enlightening overview*, explaining the essential aspects of an electrolysis cell and the effects of the corrosive environment. He underpinned, amongst others, the need to develop new catalysts using cheap and abundantly available materials, to improve the membrane electrode assemblies and porous transport layers, and to protect the bipolar contact plates through advanced coatings.

His take-home message was that however useful the improvement of such individual components, achieving real progress will require the understanding of the complex interplay of the components in a working electrolyzer. Collaboration between knowledge institutions and companies, therefore, will be paramount in positioning for (new) component suppliers to make innovative contributions to electrolyzer development.

Lively discussion: ‘ Interplay is key’!

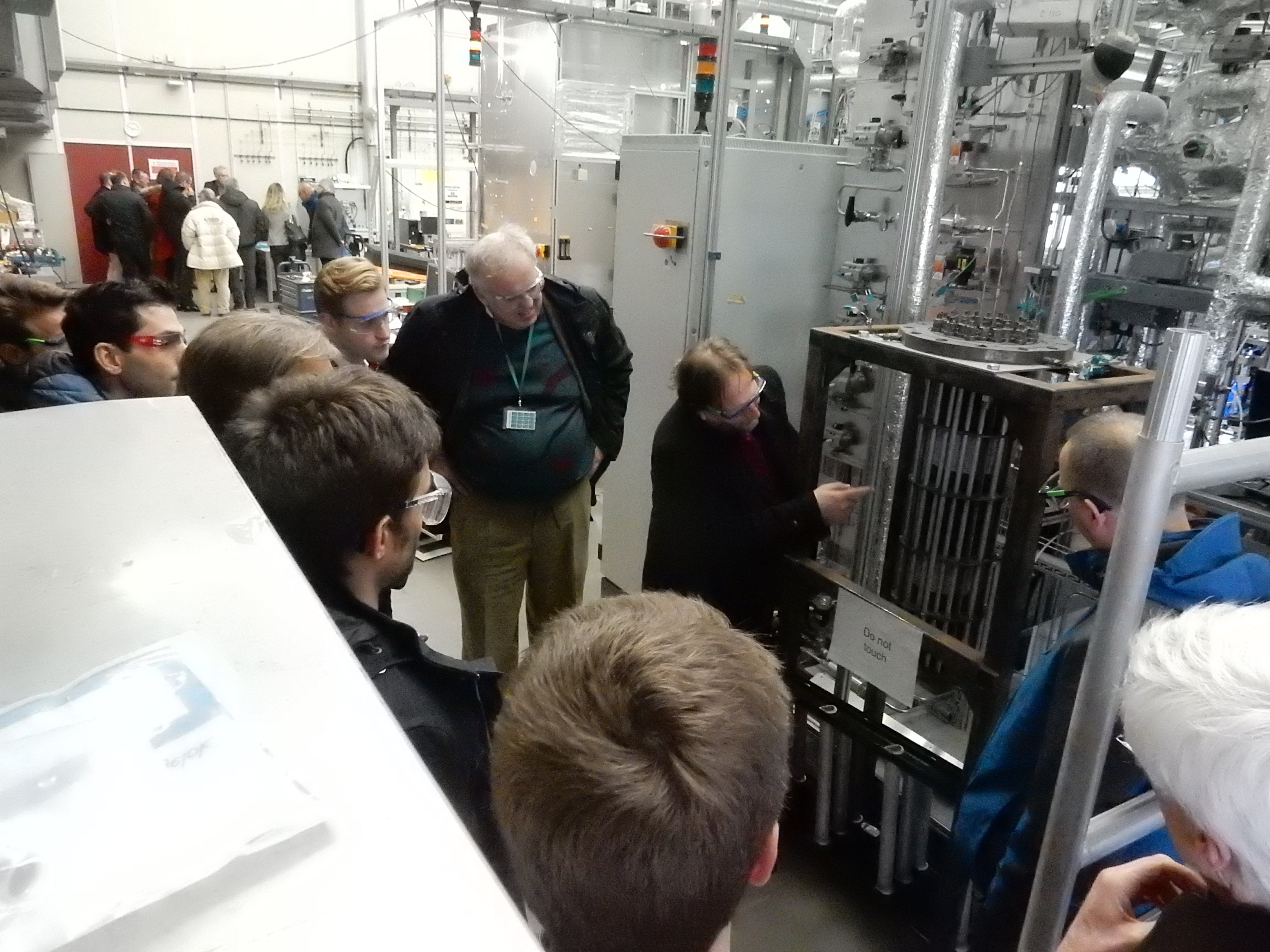

During a tour along with the ECN∙TNO research facilities and in break-out sessions later in the afternoon, the participants engaged in a lively discussion. It turned out ideas of contributing to the further development of electrolysis were manifold. This concerned amongst others the development of catalysts and materials for proton exchange membrane and electrodes, the fabrication of components and the development of testing protocols.

Community of Practices

As a new activity for its Business Community, VoltaChem aims at building a 'Community of Practice' focused on electrolyzer supply chain development. Pending the evaluation of the workshop, VoltaChem proposes to organize more events about specific electrolyzer topics and issues. In the future, more Communities of Practice (CoPs) will be started as business groups with a shared interest in specific technologies. These will develop along the VoltaChem program lines, focus on joint technology development (low TRLs, pre-competitive developments), and have strong ties to academia – without being an academic network. Each CoP will have unique activities tailor-made to the interests of the members involved. CoP’s will exist next to regular Business Community meetings where all members are invited. Existing community members can join CoP’s free of charge.

Stay in touch!

Do you want to keep in touch with electrolyzer supply chain development? Please contact our VoltaChem team members: Arend de Groot - technical lead of VoltaChems Power-2-Hydrogen - or Lennart van der Burg - business developer Power-to-Hydrogen.

If you are interested to join our VoltaChem community, please contact our community manager Monique Rijkers. Or fill in our Interested-form, and Monique will get back to you asap.

*Downloadable presentations from the workshop:

- Introduction

- Hydrogen supply chain for distribution

- Market development for Green Hydrogen

- Overview of PEMWE

Share this page: